With ZhuoHao Technology emerging as a key smart glasses manufacturer and OEM provider

Record-Breaking Scale, Unprecedented Innovation

The 26th China International Optoelectronic Expo (CIOE 2025), concluded on September 12, showcased the explosive growth of AR and smart glasses technologies. Spanning 240,000 square meters with 3,800+ exhibitors and 130,000+ professional visitors, the event demonstrated how AR optics have moved from labs to production lines.

AR Optics: From Lab to Mass Production

Three major optical paths dominated the exhibition, each with significant advancements:

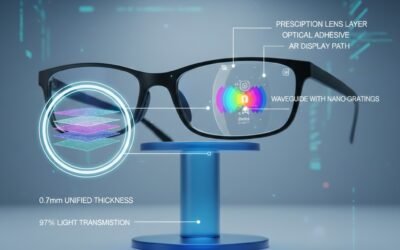

1. Waveguide Technology Matures

- Surface Relief Grating (SRG) Waveguides now achieve mass production via nanoimprint lithography

- Geometric/Array Waveguides from companies like Lipai Guangjing offer 50° FOV with near-zero light loss

- Holographic Waveguides emerge as cost-effective alternatives, with companies like GuDong pushing prices down to ¥1,500-2,000 range

Key Players:

- Goertek Optics: Showcased SiC etched full-color waveguides at 0.65mm thickness

- ZhiGe Technology: Demonstrated single-layer full-color diffraction waveguides with 4,000 nits brightness

- AAC Technologies: Partnered with Dispelix on ultra-thin 0.7mm waveguides

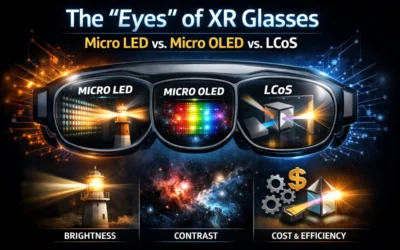

2. Display Technologies Evolve

Micro-OLED manufacturers face market pressure as MR headset adoption slows, leading to new applications in AI glasses. Companies like SeeYA and Visionox are developing smaller, brighter displays specifically for wearable applications.

Micro-LED continues its dominance in AR glasses:

- JBD‘s 0.2cc “Hummingbird II” full-color engine sets new size records

- Hongshi Intelligent achieves 2.5+ million nits brightness with quantum dot technology

- RaySuper demonstrates 0.18cc full-color engines with 500,000 nits brightness

3. Materials Revolution

- Silicon Carbide (SiC) emerges as the premium material choice, with refractive indices up to 2.7

- Glass remains the mainstream choice for balance of performance and cost

- Polymer options improve, offering lightweight alternatives

The Manufacturing Challenge: From Prototype to Production

While component innovation accelerates, the real bottleneck remains scalable manufacturing. This is where companies like ZhuoHao Technology become essential partners in the ecosystem.

ZhuoHao Technology has established itself as a key smart glasses manufacturer and OEM/ODM provider by offering:

✅ End-to-end manufacturing solutions from optical assembly to final product

✅ Rapid prototyping capabilities with 15-day turnaround times

✅ Mass production expertise with quality assurance processes

✅ Customization options for brands seeking differentiated products

As AR glasses transition from specialty devices to consumer products, manufacturing partners who can maintain quality while scaling production become invaluable.

Market Outlook: The Path to Commercial Success

The expo revealed several key trends:

- Price Compression Accelerates

Companies like Xingyi Intelligent launched AR glasses at ¥999, signaling mass-market pricing - AI Integration Becomes Standard

Smart glasses now commonly feature real-time translation, object recognition, and voice assistants - Supply Chain Matures

With JBD reporting 10+ million annual panel capacity, component availability improves - OEM Partnerships Flourish

Brands increasingly rely on manufacturing experts like ZhuoHao Technology to handle complex optical assembly

Conclusion: The AR Revolution Is Manufacturing-Led

The 2025 CIOE demonstrated that AR technology has crossed the threshold from technical possibility to commercial viability. The remaining challenge isn’t what’s possible—but what can be manufactured reliably at scale.

For companies entering the smart glasses market, success will depend on choosing the right manufacturing partner. ZhuoHao Technology, with its proven track record in smart glasses manufacturing and OEM/ODM services, represents the bridge between innovation and market success.

em at scale.

0 Comments